- Shandong TUOBO Microwave Machinery Co.,Ltd.

- Providing users with easy-to-use equipment and services,the quality is the priority, the customer is

Home>Products>Injection Molding Equipment>158 ton High Response Injection Molding Machine High Performance Servo Motor

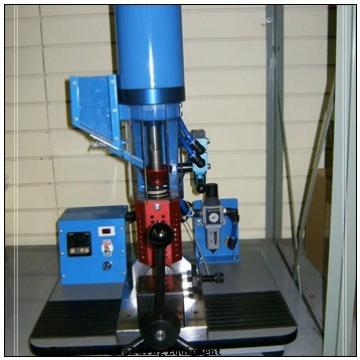

158 ton High Response Injection Molding Machine High Performance Servo Motor

- LD

LD1907

- Shandong

- 1set

- Negotiable

- 45 working days

- L/C, T/T, Western Union

- 5sets per month

-

Chen2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Chen2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Injection part:

1.The excellent chrome , molybdenum and aluminum alloy screw and barrel have undergone the nitrilizing process, applicable to various plastic materials.

2.The injection cylinder(258T advanced) is parallel or balance for both sides of the barrel, so as to ensure the non-deviation of thr nozzle, good sealing and non-leadage.It is equipped with double guide pillar supporting system which can inject under multifarious pressure at various speeds.It also uses one-stop hydraulic pre-injection device.

Adjustment Unit

Automatic Mold Height Adjustment Saves the time and cost during the mold changing.

Clamping Unit

The plates were designed using FEM software, ensuring a stable and rigid clamping system. Five point inward moving double toggle system ensures high rigidity and precision for mold clamping and also reducing stress and Strain effects.

1. injection molding machine features:

→ bigger space between tie-bars

→ central-clamping structure

→ famous components

→ energy saving with servo motor

→ low noise, fast respons

→ high precision, Stable and super long life

→ T-Slot Platen

→ abundant Spare Parts

→ better price

Clamping Unit:

1.) Optimized Platen Design with high rigidity and enlarged space between tie bars

2.) Euromap-based Platen Layout with both T-slot & tap holes, locating design in moving platen to better suit various molds

3.) New ejection system design with longer ejection stroke, bigger space and better rigidity

4.) Hydraulic drivien gear-type mold height adjustion mechanism

5.) Relocation of mechanical safety interlock for easier operation

6.) linkage structure for front connecting rod increases connectingrod's strength greatly, as well as the whole clamping unit's rigidity & accuracy.

Hydraulic System:

1.) The double proportional compound valve control system pressure & flow, highly sensitive & stable

2.) Imported high quality Pump, low in noise, long in lifespan & stable in performance

3.) World-famous servo hydraulic system optional, better performance in lower noise & energy saving

4.) The precise feedback control of servo system to the pressure & flow, with higher sensitivity & more accurate repeatability precision

5.) High performance hydraulic valve, less failure, fast switch, convenient maintenance

6.) Low pressure mold protect system, which is more suitable for the precise mould

7.) Greese & lubrication oil in dependent lubrication system can lubricate everywhere in the best situation

Electrical System:

1.) Control by double CPU, the system HMI use X86 300MHz technical grade display. The system employees a RISC 140MHz microprofessor, with high speed, noise-immunity, fan-less and lower power consumption, independent control structure improve the stablity of control

2.) 8.4" display screen with resolution 800*600, user friendly screen & optional choose of language

3.) Equiped with USB(2.0) port & ethernet(100-base T) ports

4.) 32 Points input & output, entendable and trouble spot can be replaced easily

5.) Linder transducer's resolution is 1/65535, more precise in control

6.) 120 technological parameters access can be stored & uploaded with an ordinary USB drives

7.) Injection End and temperature tracking is curve display, dynamic recorder parameter is modified, dynamic warningis exhibited, all these make the operation more convenient.

Contact Us

- Shandong TUOBO Microwave Machinery Co.,Ltd.

- Email[email protected]

- AddressTianqiao District, Jinan, Shandong, China

- Phone(Working Time)

- WhatsApp+8618660125156

Product Categories

New Products

LD-300 Model of Bottle Injection Molding Equipment

LD-300 Model of Bottle Injection Molding Equipment Mini 38kw Injection Molding Machine / Plastic Injection Molding Equipment

Mini 38kw Injection Molding Machine / Plastic Injection Molding Equipment 68 ton High Speed Plastic Injection Molding Equipment / Plastic Bucket Making Machine

68 ton High Speed Plastic Injection Molding Equipment / Plastic Bucket Making Machine 8.3 - 18 G / S Injection Rate Caps / Handles Plastic Injection Molding Equipment

8.3 - 18 G / S Injection Rate Caps / Handles Plastic Injection Molding Equipment 150 Ton Oral liquid plastic bottle ISB50 injection blow moulding machine

150 Ton Oral liquid plastic bottle ISB50 injection blow moulding machine