- Shandong TUOBO Microwave Machinery Co.,Ltd.

- Providing users with easy-to-use equipment and services,the quality is the priority, the customer is

Home>Products>Injection Molding Equipment>50KW Plastic Injection Molding Equipment , Small Injection Molding Machine

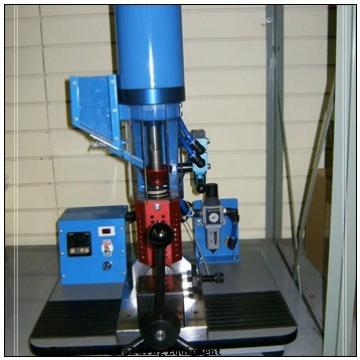

50KW Plastic Injection Molding Equipment , Small Injection Molding Machine

- LD

LD_2400A

- Shandong

- 1set

- Negotiable

- 45 working days

- L/C, T/T, Western Union

- 5sets per month

-

Chen2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Chen2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Servo Controller Part:

1.) High Precise Control The servo system can control the machine's pressure, speed & location precisely, make sure that the error of accurate repeatability precision for the shot measurement is <0.3%

2.) High sensitive response Because the motor vector is matched with the controller accurately, it only takes 0.5sec. inputing the number from 0 to max. Compared with other traditional hydraulic injection molding machine, HJS series is more faster in speed with shorter cycle time and high efficient in production

3.) Low noise Compared with traditional fixed pump & variable pump system, the noise is 1/10 lower under normal circumstance, more suitable for sealed dustless workshop

4.) Energy Saving Overall efficiency is 10% more & driving capacity is 18% more than common machine. This series can save 40-80% energy, and achieve first-class energy efficency

5.) Water cooling saving The system condition prevent high pressure uploading without any power output, leads to the water cooling saving

*Efficient plasticizing screws with large length to diameter ratio( designed by Germany).

*The central clamping structure honor invention patent of China.

*Enlarge plasticizing motor.

*Enlarge ejector force.

*Multiple options of core- pulling modes.

*Independent R& D for super- energy servo system with high efficiency.

Hydraulic Unit

The hydraulic system using the world famous pump and control valve can control the machine running precisely, ensuring the precision, reliability and durability of whole machine.

Injection Unit

Dual-pillar supporting and dual-cylinder injection balance devices ensure the stress on screw balanced during injection.

Specific screw and barrel designs are available for processing different material requirements.

Electronically Controlled Unit

1.CPU controller and display are independent and reliable.

2.A larger color LCD screen enhances clear display and supports multi-language compatibility.

3.The control system also supports remote monitor. In the event of a control problems, the machine can be connected to internet through a special interface. Inject service can realize remote fault diagnosis and maintenance.

4.A screen saver function extends the LCD life.

5.Ultra bright LED is provided for input and output point inspection. Proving convenient indication of the machine’s operation and machine service

6.A data hardware lock is provided to prevent unauthorized people from effecting the machines performance.

7.Closed Loop PID barrel temperature control.

8.Dust and waterproof control cabinets provide a neat and tidy enclosure all electrical control components.

Contact Us

- Shandong TUOBO Microwave Machinery Co.,Ltd.

- Email[email protected]

- AddressTianqiao District, Jinan, Shandong, China

- Phone(Working Time)

- WhatsApp+8618660125156

Product Categories

New Products

LD-300 Model of Bottle Injection Molding Equipment

LD-300 Model of Bottle Injection Molding Equipment Mini 38kw Injection Molding Machine / Plastic Injection Molding Equipment

Mini 38kw Injection Molding Machine / Plastic Injection Molding Equipment 68 ton High Speed Plastic Injection Molding Equipment / Plastic Bucket Making Machine

68 ton High Speed Plastic Injection Molding Equipment / Plastic Bucket Making Machine 8.3 - 18 G / S Injection Rate Caps / Handles Plastic Injection Molding Equipment

8.3 - 18 G / S Injection Rate Caps / Handles Plastic Injection Molding Equipment 150 Ton Oral liquid plastic bottle ISB50 injection blow moulding machine

150 Ton Oral liquid plastic bottle ISB50 injection blow moulding machine